Last winter in Marmaris our friends Randal and Ruth on Dora Mac showed us over their Chinese- built 50 ft displacement trawler. Yes, they had motored from China in case you're wondering (apart from a lift through the Red Sea.......Randal might be an adventurous type, but he ain't stupid). I was enamoured of the Alaskan Lugger diesel. Cruising revs were about 800 or 900, compression ratio real low and Randal used to throw his used oil, after running it through a filter, into the diesel tank. And the Lugger just kept going. And has done for many years. You can probably hand crank it. He certainly didn't have any issues with trying to dispose of old oil. I suspect Ruth probably chucked the used oil from the french fries in there too. When I asked him what he thought about the quality of diesel these days, bio diesel issues, FAME (fatty acid methyl esters) in diesel, biocides and cetane enhancers, he smiled wryly and showed me that set up on Dora Mac. He probably puts a quart of alcohol in the tank if he suspects that water might be a problem? Randal is a boy from West Virginia, spent a lifetime around cars and does his homework carefully. He chose his engine wisely for the type of travelling he was going to be doing.

We didn't.

In 2012 we had severe issues with diesel bug in our fuel. It cost us a lot for a new high pressure pump and ten injectors nozzles in total. A king's ransom. And they couldn't be repaired or cleaned. I religiously pumped samples from the bottom of our fuel tank (Hallberg Rassy install a dedicated sump and pump for that very purpose) without seeing any water. Our Racor filters were ALWAYS spotless, no water in the bowls either. The Italian Volvo Penta mechanics assumed, as I did, that the fuel was clean. Certainly looked it. The Westerbeke gen set didn't miss a beat. But the Volvo Penta D3 common rail engine just DIED. Several times. The injector nozzles were blocked with what looked like black tar, and presumably the same inside the pump. The Bosch service centre in Messina in Sicily could not get the injectors to spray fuel at 60 bar, that's how bad it was.

So what was this stuff? And why didn't we see any evidence on 5 and 10 micron filters? Or water in Racors? Why did the old Westerbeke keep chugging along all the time and the Volvo stop?

With hindsight my guess is that the previous owner had not used any biocides in Enki's tanks. When I filled the tanks in Port Napoleon in November 2011 before leaving her for the winter, I probably got some dodgy fuel. My habit over the past 20 years of boat ownership has been to use a biocide. Starbrite has been my potion of choice, and hey, there it was on the chandlery shelf in Port Napoleon. So in it went, and off I went back to Australia.

Our troubles began about 40 or 50 hours of engine time into our trip in spring 2012. Whatever the Starbrite MAY have released into the fuel from the mass of black gunk in our tanks, and/or whatever MAY have been in the load of fuel we bought, simply killed the very sophisticated, very high pressure, electronically controlled common rail fuel delivery system on Enki's Volvo Penta engine.

Not good.

So even before we had made the decision to swap the Volvo for a Yanmar (see the Engine Swap post below this) I had determined that a fuel cleaning system was a priority for us. Independently cycling fuel frequently and regularly through another Racor 500, using various filter catridges from 30 down to 2 microns seemed to be the most basic thing we could do. As well as opening up our two fuel tanks and cleaning them. We didn't do this when we bought Enki.....should have done. This was something I could do myself back in Marmaris. Pics and details below.

Talking about biocides and/or additives opens a veritable pandora's box of conflicting claims and opinions, science and faith. The only biocide I found that was endorsed by a number of engine manufacturers such as MAN, MTU, Deutz, DAF and Mercedes Benz etc was a German product called Grotamar 71 and Grotamar 83 for bio diesel. Shell Netherlands apparently uses this product in its storage tanks in Europe. I emailed Volvo Penta asking their advice on this matter. Twice. No answer at all.

I looked at the Yanmar owners manual for the new engine we have installed and it clearly states "Do not use Biocide." Yet on the internet, the Yanmar distributor for the USA, Mack Boring, clearly recommends using a biocide product called Killem. Go figure. Lots of stuff on the web too about owners being nervous about potential warranty status in the USA if they follow the distributors advice.

Last year, in some state of desperation, we installed an Algae-X magnetic fuel conditioner. Probably more snake oil than science, BUT there was one fitted on our previous boat and we NEVER had a problem with fuel. But heck, when dirty fuel has cost you upwards of ten grand, whats two hundred dollars?

This coming season we will have clean fuel tanks and a polishing system, selectable for either of the 400 litre tanks, that can circulate at least 200 litres an hour through a separate Racor 500 filter. The grunt is from a Walbro 24v fuel pump. We have a spare.

24V Walbro pump and Racor 500 filter mounted on marine ply

Filter and pump over bilge.

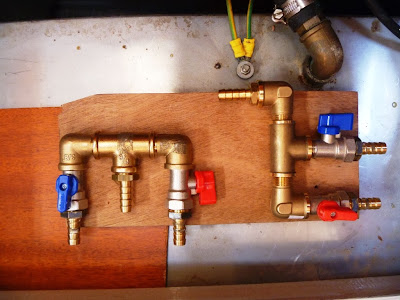

Manifolds on top of port side tank

3/8 inch fittings and 10mm fuel hose

Manifolds colour coded for each tank

Tank selection conveniently under

saloon access board by companionway steps.

We didn't.

In 2012 we had severe issues with diesel bug in our fuel. It cost us a lot for a new high pressure pump and ten injectors nozzles in total. A king's ransom. And they couldn't be repaired or cleaned. I religiously pumped samples from the bottom of our fuel tank (Hallberg Rassy install a dedicated sump and pump for that very purpose) without seeing any water. Our Racor filters were ALWAYS spotless, no water in the bowls either. The Italian Volvo Penta mechanics assumed, as I did, that the fuel was clean. Certainly looked it. The Westerbeke gen set didn't miss a beat. But the Volvo Penta D3 common rail engine just DIED. Several times. The injector nozzles were blocked with what looked like black tar, and presumably the same inside the pump. The Bosch service centre in Messina in Sicily could not get the injectors to spray fuel at 60 bar, that's how bad it was.

So what was this stuff? And why didn't we see any evidence on 5 and 10 micron filters? Or water in Racors? Why did the old Westerbeke keep chugging along all the time and the Volvo stop?

With hindsight my guess is that the previous owner had not used any biocides in Enki's tanks. When I filled the tanks in Port Napoleon in November 2011 before leaving her for the winter, I probably got some dodgy fuel. My habit over the past 20 years of boat ownership has been to use a biocide. Starbrite has been my potion of choice, and hey, there it was on the chandlery shelf in Port Napoleon. So in it went, and off I went back to Australia.

Our troubles began about 40 or 50 hours of engine time into our trip in spring 2012. Whatever the Starbrite MAY have released into the fuel from the mass of black gunk in our tanks, and/or whatever MAY have been in the load of fuel we bought, simply killed the very sophisticated, very high pressure, electronically controlled common rail fuel delivery system on Enki's Volvo Penta engine.

Not good.

So even before we had made the decision to swap the Volvo for a Yanmar (see the Engine Swap post below this) I had determined that a fuel cleaning system was a priority for us. Independently cycling fuel frequently and regularly through another Racor 500, using various filter catridges from 30 down to 2 microns seemed to be the most basic thing we could do. As well as opening up our two fuel tanks and cleaning them. We didn't do this when we bought Enki.....should have done. This was something I could do myself back in Marmaris. Pics and details below.

Talking about biocides and/or additives opens a veritable pandora's box of conflicting claims and opinions, science and faith. The only biocide I found that was endorsed by a number of engine manufacturers such as MAN, MTU, Deutz, DAF and Mercedes Benz etc was a German product called Grotamar 71 and Grotamar 83 for bio diesel. Shell Netherlands apparently uses this product in its storage tanks in Europe. I emailed Volvo Penta asking their advice on this matter. Twice. No answer at all.

I looked at the Yanmar owners manual for the new engine we have installed and it clearly states "Do not use Biocide." Yet on the internet, the Yanmar distributor for the USA, Mack Boring, clearly recommends using a biocide product called Killem. Go figure. Lots of stuff on the web too about owners being nervous about potential warranty status in the USA if they follow the distributors advice.

Last year, in some state of desperation, we installed an Algae-X magnetic fuel conditioner. Probably more snake oil than science, BUT there was one fitted on our previous boat and we NEVER had a problem with fuel. But heck, when dirty fuel has cost you upwards of ten grand, whats two hundred dollars?

This coming season we will have clean fuel tanks and a polishing system, selectable for either of the 400 litre tanks, that can circulate at least 200 litres an hour through a separate Racor 500 filter. The grunt is from a Walbro 24v fuel pump. We have a spare.

24V Walbro pump and Racor 500 filter mounted on marine ply

Filter and pump over bilge.

Manifolds on top of port side tank

3/8 inch fittings and 10mm fuel hose

Manifolds colour coded for each tank

Tank selection conveniently under

saloon access board by companionway steps.

Dear Alex, It must be satisfying to have all the new hardware in place - apparently with remarkably little hassle or collateral damage. I have a couple of questions about the polishing circuit: 1) Does the Walbro pump sit on the intake or exit side of the filter (i.e. does it suck it or push it through the Racor filter)? 2) I read somewhere the max lift of the Walbro is 30cm which wouldn't be a problem where you've mounted it in the bilge cavity. I'm tempted to mount my pump/filter combo on the port side of engine room where existing (single) engine and (single) generator primary filters currently live. Do you see any problem in doing so in terms of length of run and course of fuel lines, lift height etc? 3) I assume from your description that one of the 3 way valves is dedicated to uptake and the other to return (i.e. both reds open and blues closed when polishing port tank)? 4) Did you add additional stop cocks to the fuel tank uptake & return elbows? 5) What metal pipe and diam did you use for fuel tank uptake and return pipes and did you site the uptake from tank bottom with return to top to maximally separate intake and return fuel streams? Cheers SY Sea Cloud

ReplyDeleteHi Sea Cloud!

DeleteWalbro pump is 24V FRB2 model rated at 43 GPH (USA). Specs from Walbro indicate dry lift self prime of 300cm if check valve used. Opted not to use check valve as my lift nowhere remotely near that. Pump mounted on pressure side i.e. fuel goes through the Racor FIRST....it's sucked through by the pump. Reason is that if pump on vacuum side will emulsify water in fuel and limit the effectiveness of Racor turbine in removing any water.

I had no room in engine bay without major rerouting of copper fuel lines as ENKI already has three Racors there plus our second alternator mount complicating things. See no problems on Sea Cloud in relation to leading hoses,lift etc. No additional stopcocks used. Yes one three way is for pickup and the other for return. Colour coding is to easily identify which tank is being serviced. Used 3/8" male threads to 3/8" hose barb fittings and then 10mm ID approved fuel hose.

Fuel tank pickup pipes were welded onto the HR supplied pickup manifold. I removed this and took to welding shop and had them use same diameter s/s pipe to exactly same depth and pickup angle. Starboard side trickier than port because all the fuel pickups are from starboard tank. Although not difficult.

Fuel return pipes done the same way.... they extend approx 10 cm from top of tank and face forward, aimed at tank forward wall to facilitate mixing and swirling of fuel in this fwd section. Baffles aft of this still limit the stirring effect somewhat.

Welding took an afternoon and cost about 60 TL.

Later modification was to put closed cell foam back on ply mounting board to minimise noise. Result now very acceptably quiet.

An alternative would be the FACET solid state fuel pumps....I suspect much quieter, although would need to check dry lift specs vs capacity etc.

Dear Alex, many thanks for clarification. I'm planning to use the existing starboard "sampling" take up pipe and sacrifice the sampling option because all my sampling returned pristine fuel from a fouled tank that stopped the engine. I might simply measure the length to bottom of port tank working on assumption that Murphy will have ensured different dimensions port and starboard. I assume you put an elbow bend in top of take-off and return SS pipes? Did you weld or screw on the elbows here (with barbed fittings) or simply clamp on a 10mm ID hose straight over the SS pipe? Cheers, Sea Cloud

ReplyDeleteBuying up equipment such as this may be expensive, but if they solve your fuel woes lately, I'd say it was worth it. You already know that without fuel, you are at the mercy of the wind, and that means more effort for you and Diana. If this solved your fuel problems, you can sit back and relax while Enki II does all the work. Like you said, it's better to buy up now that buy up more expensive replacements later. Take care!

ReplyDeleteAbraham Yates @ Apache Oil Company

thanks for this

ReplyDeleteNice and useful information about fuel polishing. I really liked it.

ReplyDeleteGood work.

AFC-710-8OZ

I should say thanks for such an amazing and nice post,.

ReplyDeleteAFC-710

This comment has been removed by a blog administrator.

ReplyDelete